Plastic welding

About plastic welding

Plastic welding at Plast Solutions combines advanced technology with deep expertise in material properties. We use carefully selected techniques to create strong, durable solutions across a wide range of plastic materials, including PE, PP, PVC, PVDF, and pre-insulated pipes. Our methods ensure that the final products meet the industry´s demanding standards, which is essential for systems that transport water, wastewater, and biogas, etc.

We offer a variety of welding techniques to guarantee the highest quality for each project:

-

Hot air welding

Hot air welding

-

Extruder welding

Extruder welding

-

Electrofusion welding

Electrofusion welding

-

Butt welding

Butt welding

-

Sheet butt welding

Sheet butt welding

-

Segment welding

Segment welding

-

Socket fusion welding

Socket fusion welding

Hot air Welding

Hot air welding

Hot air welding is a versatile technique for joining thermoplastic materials. Using a hot air welder, plastic parts are heated and joined, after which the material is added, thereby creating a tight weld. This method is popular for its versatility and ability to create strong and durable joints and is often used for smaller items or when stapling.

Application

Hot air welding is used across many industries. At Plast Solutions, the method is primarily applied in the repair and fabrication of plastic components. It is also effective in the production of tanks and piping systems that require watertight connections or tack welding before other welding processes.

Advantages

This method is cost-effective, requires minimal equipment, and is ideal for both large projects and minor repairs. Its portability also makes it practical for on-site work.

Extruder Welding

Extruder welding

Extruder welding, a powerful technique for welding together larger plastic components, ideal for larger industrial projects. This method involves a plastic extruder, which is a specialized tool that heats plastic pellets or welding wire into a molten mass. This molten plastic is then expelled through a nozzle. During the welding process, the molten plastic is applied along the joint of the two plastic components to be joined.

Application

Extruder welding is particularly useful in industries where large plastic constructions are common. This includes the manufacturing of large plastic containers such as tanks and wells, piping systems, and structural components in industrial facilities. It is also widely used in the construction of water and wastewater systems.

Advantages

The primary advantage of extruder welding is its ability to handle large and complex welding tasks, making it a preferred method for projects requiring strong, intricate, and durable joints. This technique also ensures a consistent and homogenous bond between materials, which is crucial for the long-term integrity of the welded product.

Electrofusion Welding

Electrofusion welding

Electrofusion welding, also known as electro socket welding, is a specialized technique for joining plastic components, especially in piping systems. This method uses electric heating elements built into the fittings, which melt the plastic and create a strong, homogeneous weld.

Application

Electrofusion welding is ideal for piping systems in aquaculture facilities, water supply, wastewater management, and gas distribution. The technique is used to connect pipes of various diameters and is particularly suitable for installations where precision and tightness are critical. It is also a preferred method for pipeline repairs or extensions.

Advantages

The advantage of electrofusion welding is its ability to create extremely strong and leak proof welds, which is vital for infrastructure that transports fluids or gases under pressure.

The original pressure rating of the pipe is maintained

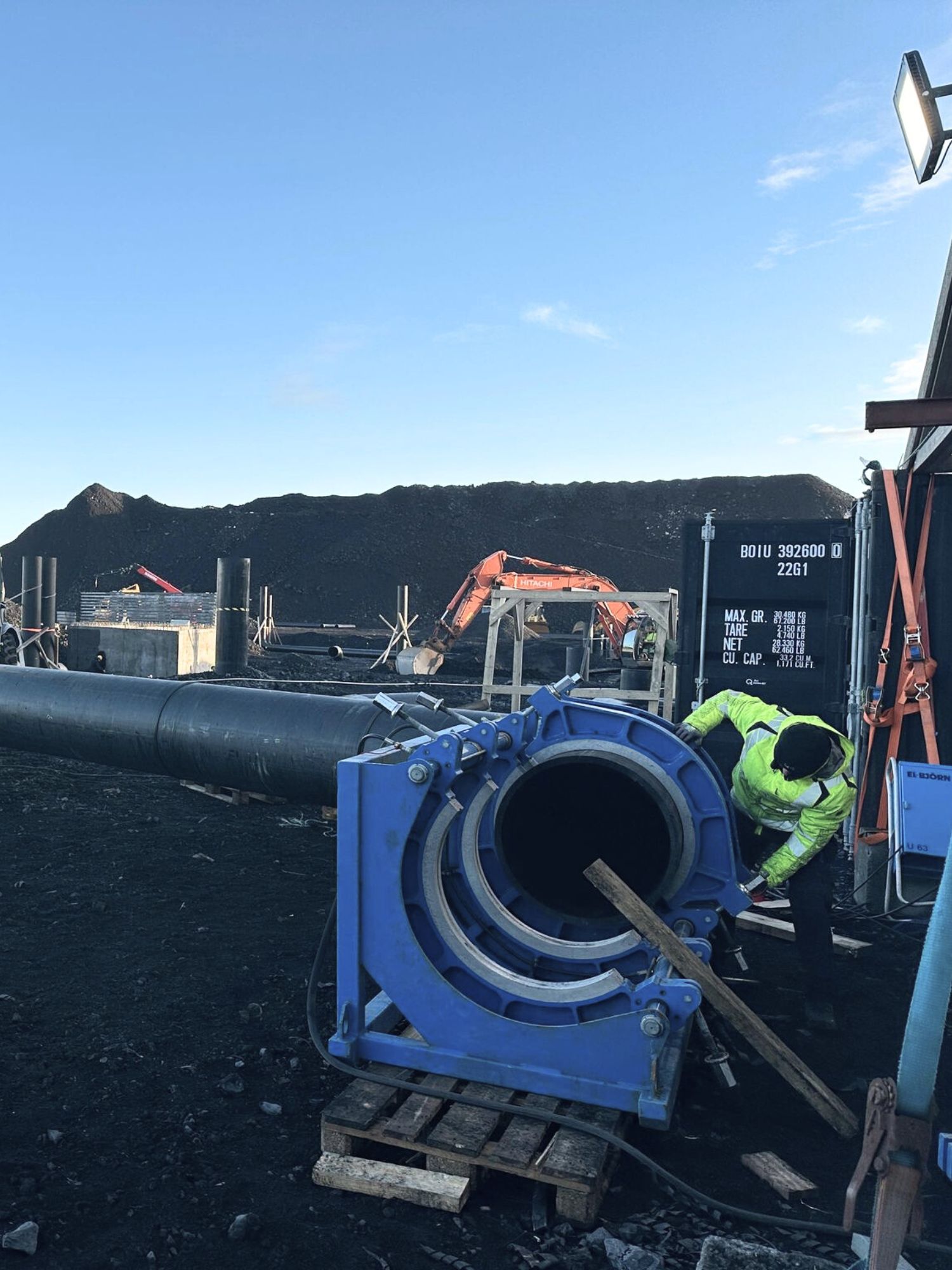

BUTT Welding

Butt welding

Butt welding is a widely used method for industrial plastics processing, especially for pipe welding of lengths and bends of all degrees. This technique involves heating the ends of two plastic parts, typically pipes, against a heated mirror and then pressing them together to create a strong and uniform weld.

Application

Butt welding is commonly used in the construction of piping systems for water, gas, and chemical transport. It is particularly valuable in industrial construction projects where durability and leak-tightness are essential. Butt welding is also a preferred technique for underground installations as it ensures long-lasting and leak-free joints.

Advantages

The main advantage of butt welding is its ability to create extremely strong and durable welds. The method is relatively simple and can be automated, increasing efficiency and reducing the margin of error. Butt welding is also known for its versatility, as it can be applied to a wide range of plastic types and pipe dimensions.

The pipe´s original pressure rating is preserved.

Sheet butt Welding

Sheet butt welding

Sheet metal stamping is a technique for precise shaping of sheet metal materials that requires high and detailed precision. This method uses advanced tools and techniques to create custom-designed shapes and components from various sheet materials.

Application

In an industrial setting, sheet butt is primarily used for the custom production of tanks and wells tailored to specific purposes and dimensions. This technique is particularly important in the manufacture of custom solutions where standard sizes and shapes are insufficient. Sheet butt welding enables the precise design of complex constructions, which is essential in projects requiring non-standard dimensions.

Advantages

The main advantage of sheet butt welding lies in its ability to create customized, robust structures with high accuracy. The technique is ideal for situations where a combination of strength, durability and precision tolerances are required. This approach ensures that the finished tanks and wells are not only functional, but also meet the highest standards of quality and performance, which is essential in demanding industrial environments.

Segment Welding

Segment welding

Segment welding is a technique for welding plastic components together with degree bends as required. By using precise welding equipment, this method can ensure strong, accurate welds when making bends in technical piping systems.

Application

Segment welding is used to manufacture complex piping systems,

It is particularly valuable in industrial construction projects where durability and tightness are essential. Segment welding is also a preferred method for installing pipes, manifolds, and technical piping, ensuring long-lasting, leak-free assembly.

Advantages

The flexibility to form desired degree bends, and its ability to create durable, precise connections make it ideal for complex industrial applications.

Segment welding is an optimal solution in situations with limited space or irregular angles, resulting in consistently high quality and reliability in the joints.

Socket fusion Welding

Socket fusion welding

Socket fusion welding is a technique that uses a cylindrical mandrel to expand the pipe ends, after which heat is applied to melt and join them. This method is unique as it combines mechanical expansion and thermal fusion, ensuring a precise and homogeneous connection of plastic components.

Application

The technique is often used to attach smaller studs to larger items such as sensors, pressure gauges, and similar devices. In addition, socket fusion welding is a recognized solution for joining pipes using specialized mandrel fittings. It is commonly applied in industries such as pharmaceuticals.

Advantages

Socket fusion welding with mandrel fittings ensures accurate and leak-proof connections between plastic parts, which is essential in environments where tightness and long-term durability are required. Compared to conventional welding methods, this technique reduces the risk of leaks and ensures a higher degree of consistency and reliability in the welds.